Spellman High Voltage Power Electronics Laboratory

Mission

Utilize the advances in Wide Bandgap semiconductors to enable efficient and compact high power density electronics for automotive, grid and aerospace applications. The Spellmann Lab and CIEES are setting up a test microgrid at the Advanced Energy Center. The demonstration grid will include intelligent energy dispatch and connected sensing technologies. The project will develop a universal management system for the rapid deployment of diverse energy storage assets (such as batteries, supercapacitors, flow batteries and generators) and loads (resistive, inductive and capacitive) to the microgrid. The demonstration uses energy storage products from NY companies, BrenTronics LLC and Ioxus Corp.

Research

Dr. Fang Luo, The Spellman High-Voltage Lab Director Dr. Fang Luo, The Spellman High-Voltage Lab Director |

Wide-bandgap devices (WBG), such as Silicon-carbide (SiC) Metal–Oxide–Semiconductor Field-effect Transistor (MOSFET) and Gallium-Nitride (GaN) High-Electron Mobility Transistor (HEMT) hve been popular in recent years because of improved switching performance, which enables higher switching frequencies with limited switching loss, reduces current ripples and size of passive components and increases converter power density and efficiency. These are highly desirable features for electric vehicles, microgrids and future electric airplanes. The tendency in the modern power-electronic application is the ever-increasing operating voltage of the systems. The higher voltage allows reducing the size and weight of conductors.

In 2021, a regional manufacturer of custom high-voltage power systems, Spellman High-Voltage

Corp. and Dr. Fang's group teamed up to advance the next generation of power electronics

by setting up a Spellman High-Voltage Lab at CIEES. While medium voltage to low voltage

power conversion is a much larger market – e.g., low voltage power is used by all

consumer electronics, computers, cell phones – it is high voltage power (1,000 – 500,000

volts) that is required for the systems manufactured by Spellman's clients in medical

imaging, security screening, industrial quality control, food inspection, semiconductor

manufacturing, underwater data transmission, nanotechnology, analytical instrumentation

and many other applications. WBG devices are ideally suited for the next generation

of high-voltage, high-power systems.

Advanced High-Power Inverters Based on Wide-Band Devices

High switching speeds of Wide Bandgap devices makes filtering the parasitic electromagnetic emission more challenging. Among the passive components in particular, passive filters are still a major bottleneck to enabling higher power density. Conventionally, a second-order passive filter is used to mitigate the parasitic emission. These passive filters tend to be bulky and could occupy up to 30% of the system volume.

Dr. Fang's team developed zero-phase filtering, which is a method to implement filtering without any phase distortion. This methodology was applied in an active digital filter to compensate the phase distortion introduced by the noise-sensing passive high pass filter. The concept was demonstrated using a simple feed-forward voltage-sense voltage-cancellation filter for differential mode noise attenuation. Converter test results show attenuation of 46 dB attenuation around 120 kHz. This is the highest attenuation reported with a single order filter around 150 kHz with analog or active digital filters.

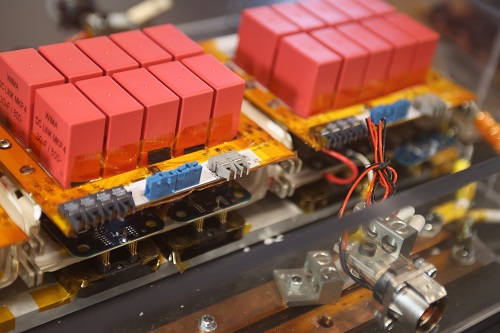

Packaging of power modules

WBG module packaging is another research direction of the Lab. WBG devices are especially

sensitive to parasitic inductances in interconnections. Optimizing the power loop

at the packaging level is one of the optimal solutions for inductance minimization.

Aligned with this concept, emerging packaging technologies are being developed, such

as direct-lead-bonding structures, structures based on flexible PCB, and PCB embedded

packaging. Dr. Fang's group is working on hybrid packaging structures that can reduce

stray inductance and enhance gate drive synchronization. As a result, faster-switching

speed and lower switching loss can be achieved. The modules utilize a direct-soldered

coldplate, which reduces the junction-to-coolant thermal resistance because of eliminated

thermal grease resistance.

Power electronics for all-electric aircraft

The future aviation industry faces numerous challenges, including improved overall

efficiency and volumetric density, reduced emissions, and lowered dependence on carbon-based

fuels. The aviation industry emitted 905 million tonnes of CO2 in 2019. This number

is expected to substantially increase as the global aviation industry demand grows

in the future. In response to the forecasted situation, the international civil aviation

organization (ICAO) set goals of not only keeping CO2 emissions at the 2020 level,

but also targeting a 50 % reduction in net CO2 emissions by 2050, as of 2005 levels

of 650 tonnes of CO2. In order to realize low carbon propulsion targets, the national

aeronautics and space administration (NASA) has adopted two primary paths: enabling

the use of alternative fuels and shifting to innovative propulsion systems, such as

fully electric aircraft. In order to address the long term challenges associated with

fully electric aircrafts, NASA has funded exploring the usage of liquid Hydrogen (LH2)

energy storage. The project, "Cryogenic High Efficiency Electrical Technologies for

Aircraft" (CHEETA) aims at developing a fully electric aircraft that has an on-board

cryogenic system to store LH2, which will be used for fuel cell energy conversion.

As part of the cryogenic converter development, Dr. Fang's team developed numerous cryogenic subsystems, including driver boards and double pulse test platforms using off-shelf components. Both the boards were integrated and their performance was successfully tested at room temperature and inside Liquid Nitrogen, 77 K environment. Using the designed subsystems, dynamic characterization of GaN switching module was performed for the first time. Overall switching loss reduction of as much as 62 % was observed at device-rated current. The team developed a complete list of off-shelf components which were utilized in the design. As part of future work, converter testing under rated conditions is on-going, delivering results with superconducting inductor at temperatures such as ∼ 20 K.

Selected publications

[1]Z. Yuan et al., "Insulation and Switching Performance Optimization for Partial-Discharge-Free Laminated Busbar in More-Electric Aircraft Applications," Ieee Transactions on Power Electronics, vol. 37, no. 6, pp. 6831-6843, Jun 2022, doi: 10.1109/tpel.2021.3137839.

[2]Z. Yuan et al., "A High Accuracy Characterization Method of Busbar Parasitic Capacitance for Three-level Converters Based on Vector Network Analyzer," in 26th Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Electr Network, Jun 14-17 2021, in Annual IEEE Applied Power Electronics Conference and Exposition (APEC), 2021, pp. 1543-1548, doi: 10.1109/apec42165.2021.9487402.

[3]Z. Yuan et al., "A 1.2 kV 400A SiC-MOSFET Based 3L-TNPC Power Module With Improved Hybrid Packaging Method for High-Density Applications," in 26th Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Electr Network, Jun 14-17 2021, in Annual IEEE Applied Power Electronics Conference and Exposition (APEC), 2021, pp. 27-32, doi: 10.1109/apec42165.2021.9487258.

[4]Y. L. Wang et al., "Space-Charge Accumulation and Its Impact on High-Voltage Power Module Partial Discharge Under DC and PWM Waves: Testing and Modeling," Ieee Transactions on Power Electronics, vol. 36, no. 10, pp. 11097-11108, Oct 2021, doi: 10.1109/tpel.2021.3072655.

[5]A. I. Emon, Z. Yuan, A. B. Mirza, A. Deshpande, M. Ul Hassan, and F. Luo, "1200 V/650 V/160 A SiC+Si IGBT 3L Hybrid T-Type N.P.C. Power Module With Enhanced EMI. Shielding," Ieee Transactions on Power Electronics, vol. 36, no. 12, pp. 13660-13673, Dec 2021, doi: 10.1109/tpel.2021.3089578.

[6]A. I. Emon et al., "Design and Optimization of 650V/60A Double-Sided Cooled Multichip GaN Module," in 26th Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Electr Network, Jun 14-17 2021, in Annual IEEE Applied Power Electronics Conference and Exposition (APEC), 2021, pp. 2313-2317, doi: 10.1109/apec42165.2021.9487307.

[7]B. Narayanasamy, H. W. Peng, Z. Yuan, F. Luo, Y. B. Chu, "Zero-Phase-Filtering based Digital Active E.M.I. Filter," in IEEE 9th International Power Electronics and Motion Control Conference (IPEMC-ECCE Asia), Nanjing, PEOPLES R CHINA, Nov 29-Dec 02 2020, in IEEE International Power Electronics and Motion Control Conference IPEMC, 2020, pp. 1910-1917,