Current Projects - Prior Results

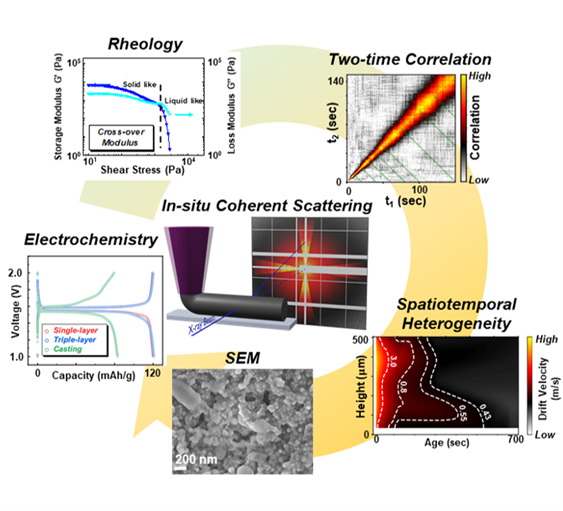

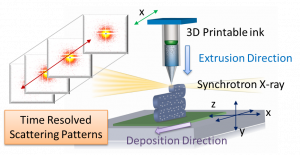

Materials Process-Structure-Property Relationship: In Situ Studies of Additive Manufacturing (3D Printing)

Figure- Time-resolved coherent X-ray scattering to study 3D printing in situ.

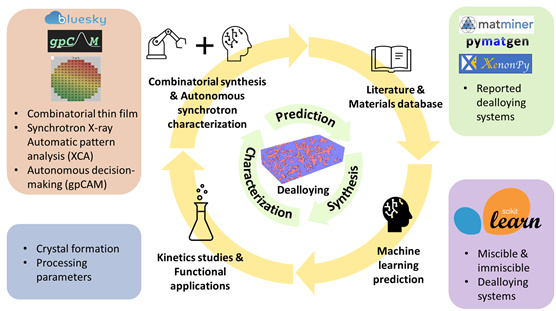

Materials Process-Structure-Property Relationship: Functional Porous Metals and Alloys and Bicontinous Metallic Composites

Figure – Study of thin film solid state Interfactial dealloying (left), and a machine-learning augmented materials design approach (right).

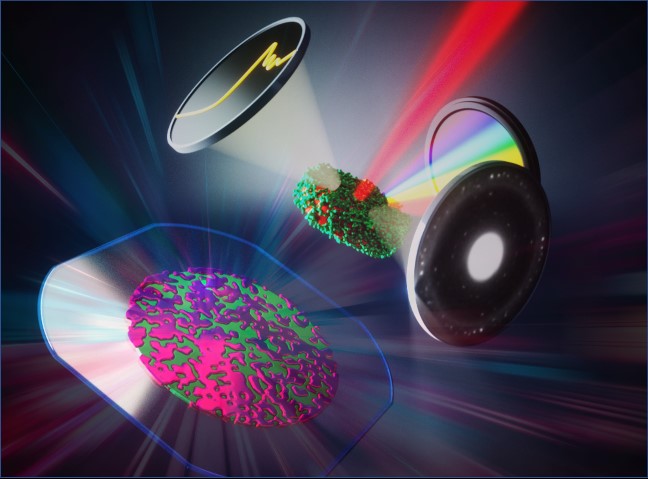

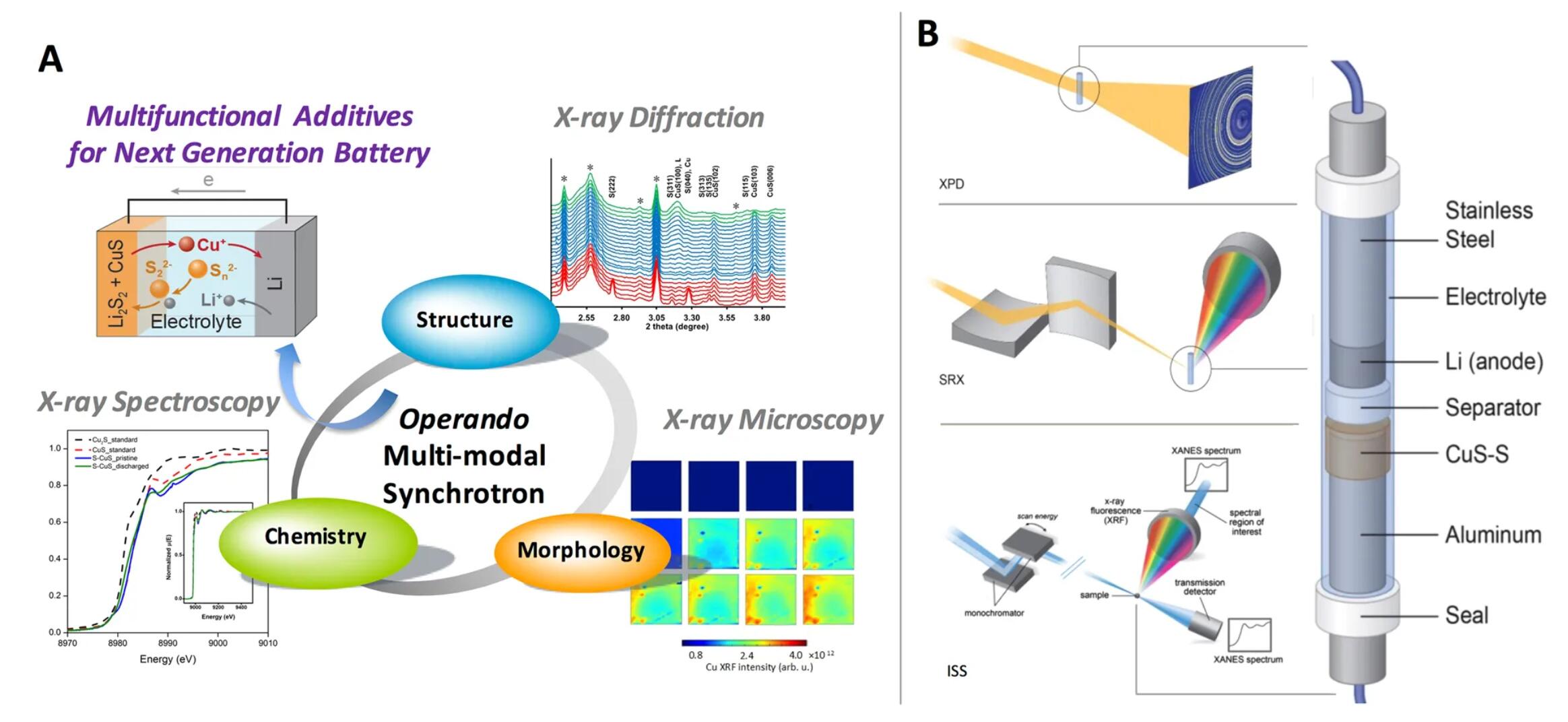

Sustainable Energy: Battery Studies with In Operando Multi-modal Synchrotron X-ray Techniques

Cheng-Hung Lin, Chonghang Zhao

Figure – Cu x-ray studies during cycling to study the structural, chemical and elemental distribution evolution in CuS-S hybrid Li-S battery electrode

Collaborator: H. Gan (Brookhaven National Laboratory)

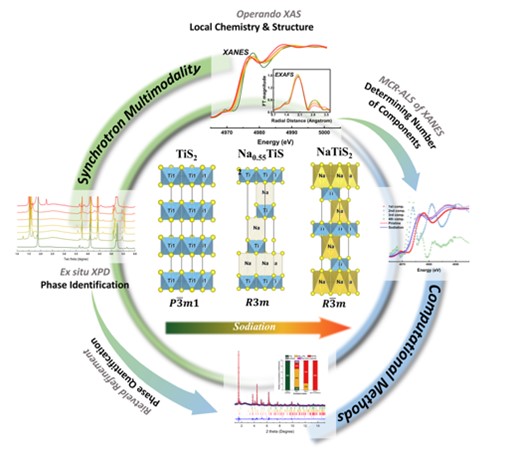

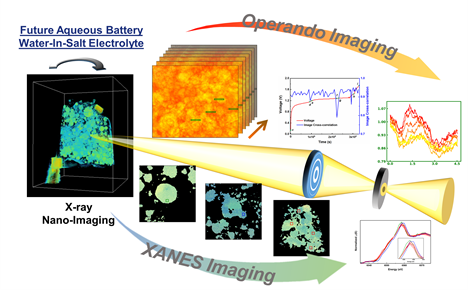

Figure -Operando and Multimodal Studies of Batteries by Advanced Synchrotron X-ray Characterization: Left – Na-TiS2 battery [1], Right - Water-in-salt Li-ion battery [2].

1. "Systems-Level Investigation of Aqueous Batteries for Understanding the Benefit

of Water-In-Salt Electrolyte by Synchrotron Nano-Imaging"

Cheng-Hung Lin, Ke Sun, Mingyuan Ge, Lisa Housel, Alison McCarthy, Mallory Vila, Chonghang Zhao, Xianghui Xiao, Wah-Keat Lee, Kenneth J. Takeuchi, Esther S. Takeuchi, Amy C. Marschilok, Yu-chen Karen Chen-Wiegart

Science Advances 6, eaay7129 (2020).

PDF Journal

2. "Operando structural and chemical evolutions of TiS2 in Na-ion batteries"

Cheng-Hung Lin, Mehmet Topsakal, Ke Sun, Jianming Bai, Chonghang Zhao, Eric Dooryhee,

Paul Northrup, Hong Gan, Deyu Lu, Eli Stavitski, Yu-chen Karen Chen-Wiegart

Journal of Materials Chemistry A (2020). Advance Article

PDF Journal

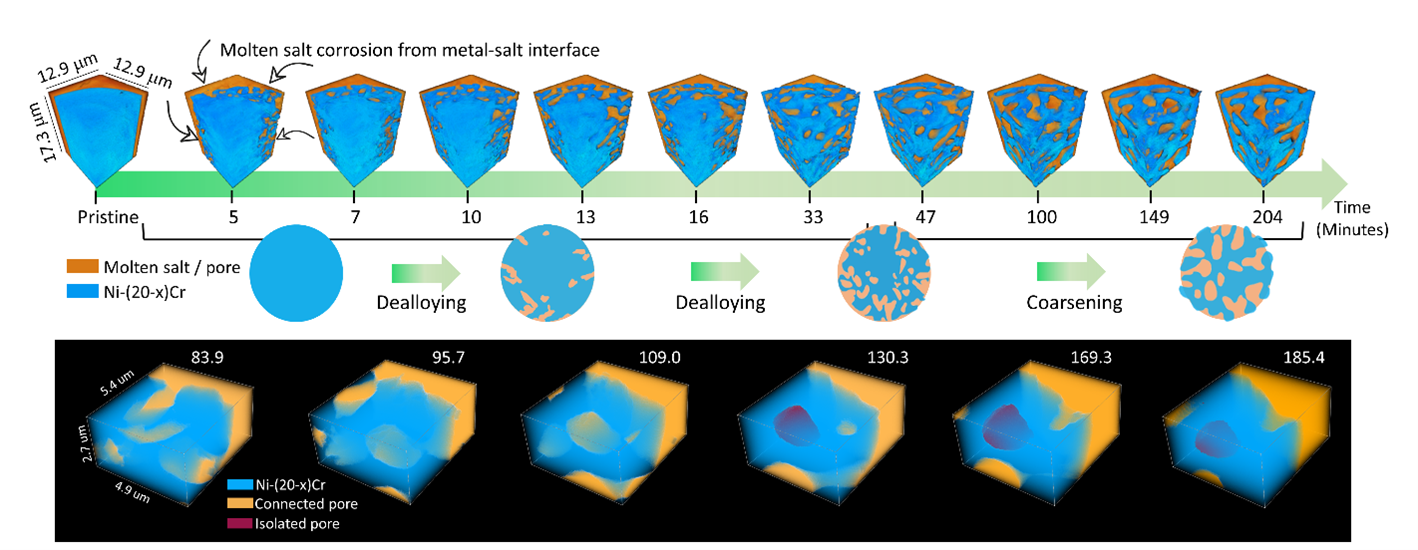

Understanding Corrosion Processes in Molten Salts

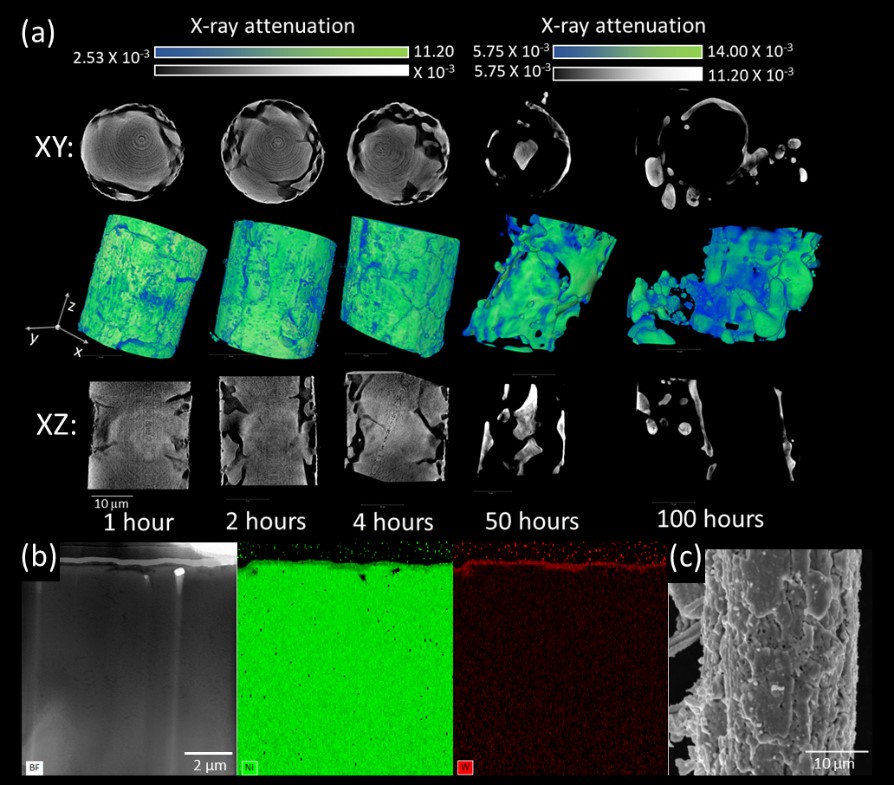

Figure- Operando X-ray nano-tomography revealing materials’ 3D morphological evolution in molten salt. [1]

1. " Formation of three-dimensional bicontinuous structures via molten salt dealloying studied in real-time by in situ synchrotron X-ray nano-tomography"

Xiaoyang Liu, Arthur Ronne, Lin-Chieh Yu, Yang Liu, Mingyuan Ge, Cheng-Hung Lin, Bobby Layne, Phillip Halstenberg, Dmitry S. Maltsev, Alexander S. Ivanov, Stephen Antonelli, Sheng Dai, Wah-Keat Lee, Shannon M. Mahurin, Anatoly I. Frenkel, James F. Wishart, Xianghui Xiao, Yu-chen Karen Chen-Wiegart

Nature Communications, (2021) , 12, p1-12.

Figure- 3D morphology reconstructed from Transmission X-ray Microscopy along with electron microscopy of nickel wire after immersion in molten salt .

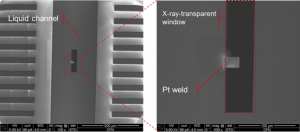

Industrial Processes: In Situ Characterization of Material Evolution in Thin Films and Surface Treatment

Figure – steel sample mounted in a liquid in situ cell to be investigated by in situ x-ray spectroscopic imaging

Collaborator: S. Petrash ( Henkel Corp.)

Materials Process-Structure-Property Relationship: In Situ Studies of Additive Manufacturing (3D Printing)

Cheng-Hung Lin, Olivia Chen , Kevin Kucharczyk

Figure – Using in situ synchrotron scattering methods, we study the dynamics of structural formation during the 3D printing and curing processes

Collaborator: L. Wiegart (Brookhaven National Laboratory), H. Gan (Brookhaven National Laboratory), D. Gersappe (Stony Brook U.)

Prior Projects

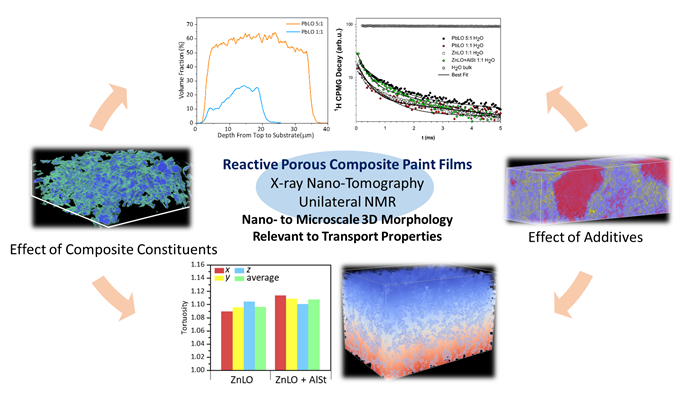

Cultural Heritage: Study the Physical Transport Phenomena in Art Works for Art Conservation

Xiaoyang Liu, Yu-Chung Lin, Bryan Conry

Working with the scientists from the Metropolitan Museum of Art, we use synchrotron X-ray imaging to study the nano- to microscale three-dimensional (3D) morphology of painting films. We investigate the connection between paints’ composition, 3D morphological properties and the transport of water and organic solvents in painting composites. Overall, this work will help to further improve art conservation process.

Figure- Characterizing nano‑ to microscale three‑dimensional morphology relevant to transport properties in reactive porous composite paint films.

Collaborator: S Centeno (Metropolitan Museum of Art)

Publication:

“Elemental and Molecular Segregation in Oil Paintings due to Lead Soap Degradation”,

Yu-chen Karen Chen-Wiegart, Jaclyn Catalano, Garth Williams, Anna Murphy, Yao Yao,

Nicholas Zumbulyadis, Silvia A. Centeno, Cecil Dybowski, Juergen Thieme,

Scientific Reports, 7:11656 (2017)

PDF Journal

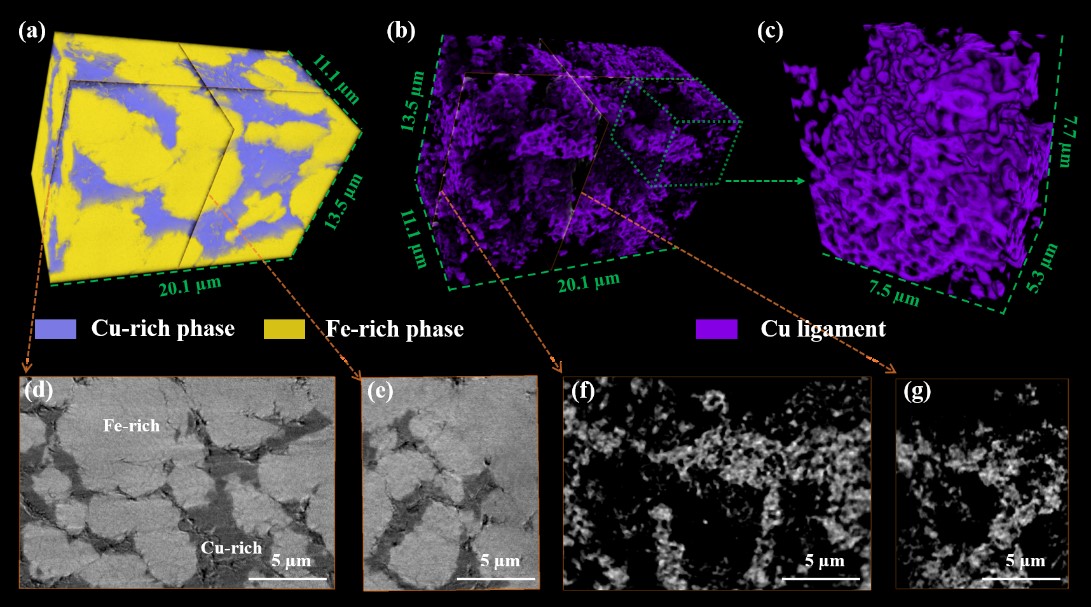

Study of Multiscale Porous Cu in Dealloying

Porous metals have drawn great attention due to their superior properties and extensive potential applications in energy storage, catalyzing carrier, detectors, etc. The ability to design the pore size distribution is critical to control the properties for different applications. Using a combination of chemical dealloying and etching methods on a combination of solid-solution, intermetallic and phase-separated metallic composites, we can design porous Cu in different pore size ranges. The nano- sized, micron-sized and bimodal sized (both nano-/micron-sized) porous Cu have been fabricated from dealloying of Cu-Al, Cu-Fe and Cu-Fe-Al alloy precursors. In order to precisely control the structure of the porous Cu and explore the relationship of the microstructure between precursor alloy and porous structure, the surface morphology, chemical distribution and 3D morphology of different alloy systems have been analyzed using a combination of electron-based methods and synchrotron-based X-ray nano-tomography.

Figure - 3D X-ray nano-tomography reconstruction of a bimodal porous Cu prepared by chemical dealloying.

Publication:

“ Designing Multiscale Porous Metal by Simple Dealloying with 3D Morphological Evolution

Mechanism Revealed via X-ray Nano-tomography ”

Lijie Zou , Mingyuan Ge, Chonghang Zhao , Qingkun Meng , Hao Wang, Xiaoyang Liu, Cheng-Hung Lin , Xianghui Xiao, Wah-Keat Lee, Qiang Shen, Fei Chen, Yu-chen Karen Chen-Wiegart

ACS Applied Materials & Interfaces (2020), 12, 2793−2804

PDF Journal

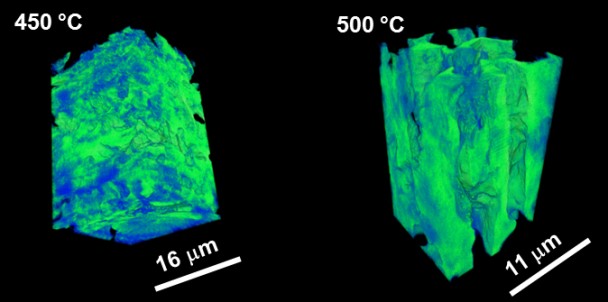

Porous materials by vapor phase dealloying

Vapor phase dealloying (VPD), utilizes the saturated vapor pressure difference between constituent elements for selectively removing one of the components from an alloy at elevated temperature. By using this emerging and versatile method, we fabricated porous materials for structural and functional applications. We used synchrotron X-ray nano-tomography to characterize the 3D morphological factors such feature size, shape, tortuosity and curvatures. The aim of our study is to elucidate the process-structure-property relationships of this novel dealloying method.

Figure - 3D morphology of porous Cu prepared by vapor phase dealloying at different temperatures.

(*current group members)